Other precision structural components for automobiles

Details:

| Application |

Product Illustration |

Product Introduction |

| ADAS |

|

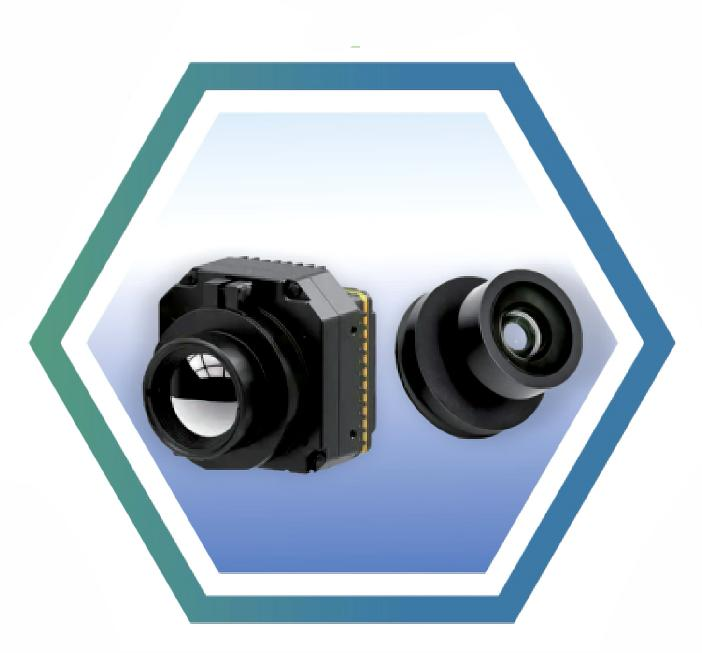

As the automotive industry moves towards intelligence, the applications of in-vehicle cameras have expanded from basic driving recorders and reversing image functions to more advanced functions such as 360° surround view, lane keeping assist, automatic emergency braking for pedestrians (AEB), driver monitoring systems, and advanced driver-assistance systems (ADAS). Especially driven by the technological demands of autonomous driving and 360° surround view, the number of in-vehicle cameras used per vehicle has significantly increased, rising from 1-2 cameras to 5-14 cameras. With the increasing demands on the performance of in-vehicle cameras, such as pixel count, detection distance, and reliability, our company has collaborated with Guangdong University of Technology on in-depth cooperation and research in the fields of material application and process innovation for in-vehicle cameras. After two years of development, we have successfully verified the cold forging process for camera housings and have achieved mass production for multiple projects. Currently, we are engaged in in-depth cooperation with several major clients in the industry. |

| BUSBAR/Multi-layer Composite Structure Busbar |  |

BUSBAR/Multi-layer composite structure busbars are high-speed channels in new energy vehicles and new energy storage power systems. They are widely used in new energy motors, battery packs, high-voltage electronic control systems, cell conductive connections, and energy storage power cabinets to achieve high-current series-parallel transmission within the system. They possess excellent electrical repeatability, low impedance, anti-interference capability, and high reliability. The company has the R&D and manufacturing capabilities for a wide range of products used in new energy electric vehicles and new energy storage, including copper-aluminum foil soft connections, multi-layer soft connections, direct bending hard connections, copper-aluminum composite busbars, and nickel-aluminum composite busbars. |

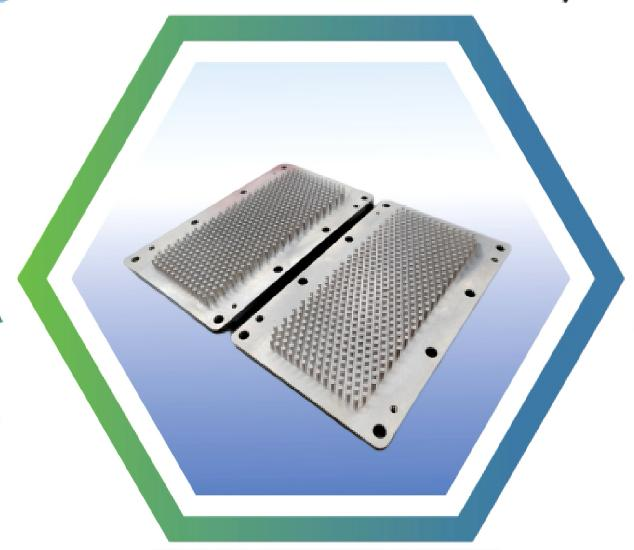

| IGBT Chip Heat Sink |

|

The IGBT chip heat sink ensures stable operation of the motor controller IGBT module even in high-temperature environments through efficient heat transfer mechanisms. Through metal substrate and heat conduction structure design, it effectively reduces the operating temperature of the IGBT module, improving its stability and service life. The company's "Taiji Needle-type IGBT Chip Heat Sink" boasts high thermal conductivity and excellent heat dissipation performance. It uses a precision cold forging process, exhibiting outstanding performance in forming accuracy, surface aesthetics, and energy saving. |

| CSS |  |

As an electrical connection component installed inside the battery module, it achieves series-parallel connection between cells, high-voltage and high-current transmission, temperature signal acquisition and transmission, and voltage signal acquisition and transmission. The product features a thin and light structure and high integration, which helps improve battery pack assembly efficiency and space utilization. It also offers advantages such as convenient customer installation and strong commonality. |

Other contents

Display terminal precision structural components

Mainly used in smart TVs, educational displays, office displays, e-sports displays, medical displays, fitness displays, and other products. Its main function is to fix the optical module of the display device, serving as one of the key structural materials for the display screen and back panel. It also plays a role in the appearance and personalization of the display device. The internal dimensions and flatness of the product significantly impact the assembly effect of the display screen, helping to improve the overall light leakage and light spot issues of the display device. The flatness and thickness of the product are crucial for the seamless integration of the overall structural material and screen, achieving an immersive viewing experience.

Precision components for digital cameras

Primarily used in the lenses and buttons of digital cameras, this product is a key component that directly impacts image quality. It strictly meets customer requirements for high standards of precision and assembly of precision optical components, and is critical for zoom and focus adjustment. The precision of Fuji Intelligent's products can reach ±0.005mm.

Other precision structural components for consumer electronics

Primarily used in the casings and buttons of recording pens/dictionary pens, educational tablets, and other products. As a key structural material for the device, providing structural support and protecting internal electronic components, the company's advanced processes and surface treatment technology give the product a superior metallic texture and exquisite appearance. The product is lightweight, has high mechanical strength, good stability, and high durability. The perfect combination of plastic and metal enhances the overall appearance, visual effect, and smooth touch of the device, significantly impacting the display effect.

Battery cell structural components

The explosion-proof valve is the only indispensable safety component in the battery cell structure, specifically used for the top covers of new energy vehicle battery cells and new energy storage battery cells. It ensures timely and effective pressure relief by opening the valve when the internal pressure of the cell abnormally rises above the rated tolerance pressure. Its key characteristics are crucial for ensuring the safety of the battery pack.

Battery tray profiles, as an indispensable key component of new energy vehicles, are the main structural components of the structural skeleton and protective shell of lithium-ion battery packs. They are mainly used in battery pack housings, battery trays, and lightweight anti-collision beams. Aluminum alloy materials, due to their lightweight, high-strength, and corrosion-resistant properties, have become the mainstream choice for battery tray profiles, helping to improve the overall performance and cruising range of new energy vehicles. This product provides a safe protective shell and structural support for the new energy vehicle battery system module, has a heat dissipation function, provides a safe and stable operating environment for the battery system, and plays a vital role.

Other precision structural components for automobiles

As an electrical connection component assembled inside the battery module, it realizes the series and parallel connection between battery cells, the transmission of high voltage and large current, the acquisition and transmission of temperature signals, and the acquisition and transmission of voltage signals. The product features a lightweight and thin structure with high integration, which helps improve battery pack assembly efficiency and space utilization. It also offers advantages such as convenient customer installation and strong commonality.

TEL

/

/

ADD

/

Address: No. 3, Xinqing 6th Road, Xinqing Science and Technology Industrial Park, Doumen, Zhuhai

Copyright © Zhuhai Fuji chinon Co., Ltd 粤ICP备2022120036号 SEO Powered by 300.cn